Rapid Scrap & FPY Loss Recovery

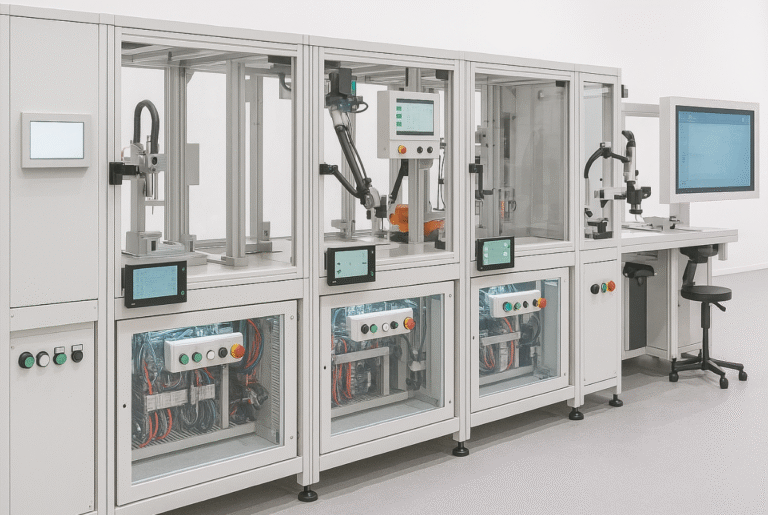

For High-Volume Automotive & Electronics Manufacturing

Former Tesla Sr. Process Engineer helping factories stabilize processes and recover KPIs fast, remotely or onsite.

My Services

Flexible Solutions for Different Production Challenges

RCA Identification

1–2 weeks

Challenges can come in by surprise and have a devastating impact.

I independently analyze your existing production data & reports to pinpoint the Root Cause.

Clear, actionable RCA report delivered fast.

Workflow

1️⃣ Kickoff call

2️⃣ Data access

3️⃣ Weekly Q&A check-in

4️⃣ RCA report

No root cause, no fee.

Solution Implementation

1-2 months

Once the root cause is clear, I work with your team to apply data-backed fixes that deliver measurable KPI gains. The focus is on improving KPI with one high-impact challenge, adding extra expert bandwidth without extra workload or headcount.

Workflow

1️⃣ On-site visit

2️⃣ Data + team access

3️⃣ Daily alignments

4️⃣ KPI target met

Base + travel fee; success bonus only if KPIs improve.

Beta

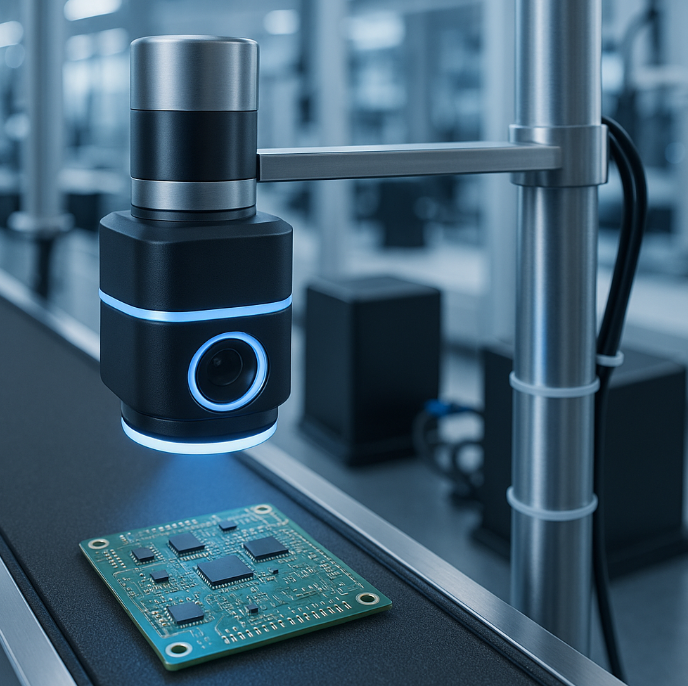

Custom Solutions / AI

Based on customer needs

AI is reshaping manufacturing.

I study your processes and integrate AI tools that boost efficiency and insights.

AI-tailored software solutions.

Workflow

1️⃣ Process review

2️⃣ Data & system mapping

3️⃣ AI tool integration

4️⃣ Efficiency gains verified

Quotation following customer needs.

Internal limits vs. External leverage

Internal

- Tunnel vision → too close to daily issues

Firefighting Focus → too many priorities competing at once

Alignment challenges → coordination across teams takes time and focus

External

-

Fresh perspective → sees blind spots clearly

-

KPI Focus → laser focused on a high impact issue

-

Unified direction → aligns people quickly around one problem and path forward

About Me

Core Expertise I Bring to Your Line

- Former Tesla Sr. Process Engineer (Inverter Ramp-Up, KPI Stabilization.

- 10+ years in Automotive & Semiconductor manufacturing.

- Specialized in rapid RCA using problem solving tecnniques.

- Certified Lean Six Sigma Green Belt, houndrands of challenges solved.

Connect on LinkedIn

Why Work With Me?

Speed & Focus

Root causes found in days, not weeks. Get a dedicated expert focused only on your problem until it’s under control.

Proven Expertise

Over 10 years in automotive and semiconductor manufacturing, solving complex issues in high-standard production lines.

Hands-On Partnership

I work directly with your team, onsite or remote, to resolve issues quickly and build solutions your people can sustain.

Risk-Free Collaboration

Pay only for my working hours when results are delivered. No long contracts, no financial risk – just measurable progress.

Industries I Serve

I specialize in a variety of production processes

Automotive

Electronics

Semiconductors

Let the Numbers Speak

Mfg. Processes Mastered

Production Problems Solved

Engineers Collaborated Globally

Frequently Asked Questions

No. I work alongside your engineers and quality staff as reinforcement. You know your process best. My role is to bring fresh perspective and focus when the team is stuck or needs backup. I use proven methods and speed to help resolve issues that your team doesn’t have time to dig into.

In most cases, I identify root causes within days, not weeks. Clear action plans are delivered quickly so production can stabilize fast.

I specialize in urgent issues like high scrap, low first-pass yield (FPY), recurring quality problems, and ramp-up bottlenecks. My methods apply across automotive, electronics, and semiconductor mass production.

Both. I can analyze data and guide solutions remotely, or join your line onsite for hands-on problem-solving, depending on what the issue requires.

My model is results-first: you only pay for my working hours when the outcomes are delivered and proven with your data. This means zero risk for you and immediate ROI.

I don’t just “fix and leave.” I transfer knowledge, document the solution, and ensure your team can sustain the improvements long-term.